With a worldwide presence in sugar industry, ITECA equipments help optimizing the crystallization process, allowing customers to fully monitor their production at the lowest cost.

For more than 25 years Its Color&Vision Department has created and developed specific equipments based on real-time image processing.

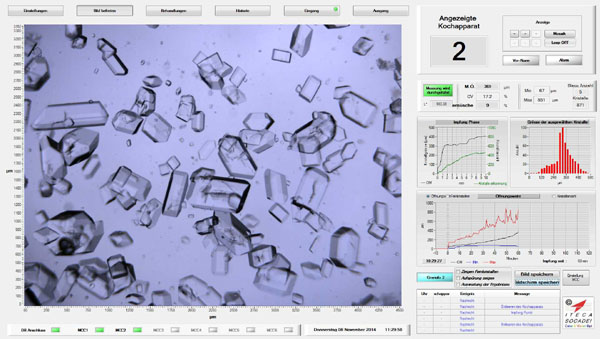

The CrystobserverŽ is an optical system that monitors the crystal growth inside the pans and calculates valuable statistical data on line (MA, CV or number of fines). It is useful at different steps along the strike: before seeding to monitor the syrup quality (detection of contaminants, air bubbles or super coarse crystals); during the graining phase to make sure the seeds enter the pan and starts growing as requested; and then all along the strike to check the crystal growth. The primary goal being to produce a good and stable massecuite quality with homogeneous crystals.

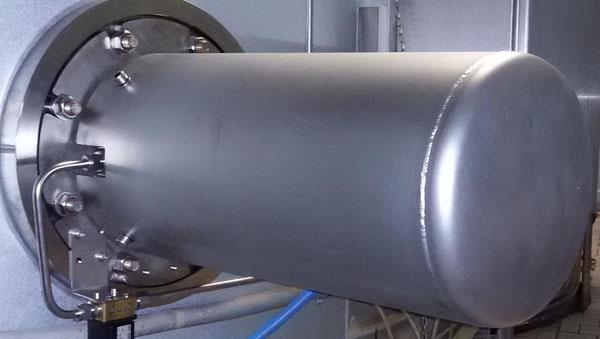

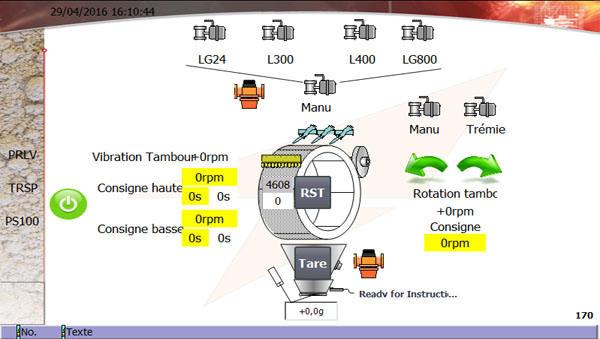

The ColobserverŽ measures with high precision the colour of the sugar (wet or dry) on-line. At the same time it automatically detects the non conformities in real-time and triggers alarms to avoid contaminating the dryer or the silos. The video of alarms allows carrying out targeted maintenance for each individual centrifuge. The washing time optimization avoids remelting good sugar while increasing the sugar production, thus bringing a fast payback

List of equipment and/or main services :

- ColobserverŽ

-

SpectrobserverŽ

-

CrystobserverŽ

-

PartsizerŽ

-

Colocompact

-

Sampling tools

Business areas : Back-end factory